Special stainless steels from VDM Metals

Special stainless steels represent a material group that is situated between the non-corrosive steels and the nickel alloys. These iron-nickel-chromium alloys differ from the ordinary non-corrosive steels by their higher alloying additions of nickel, chromium or molybdenum. Many corrosion-resistant alloys, such as VDM® Alloy 31, VDM® Alloy 800 H or VDM® Alloy 926, whose main alloying element is not nickel, but that still have a relatively high nickel content, are part of this group. Furthermore, we produce a number of not nickel-containing materials, which we also consider part of our special stainless steels.

For our high-alloy special stainless steels as for our classic nickel alloys applies: each of our alloys has a unique combination of properties, depending on their chemical composition and their manufacturing process.

We divide our nickel alloys and high-alloy special stainless steels into the following material groups:

Corrosion-resistant alloys

Heat conducting and resistance alloys

Our heat conducting and resistance alloys are characterized by relatively high and/or constant specific electrical resistance values. The materials spectrum ranges from austenitic nickel-iron-chromium alloys to aluminum-containing ferritic chrome steels like VDM® Aluchrom Y Hf.

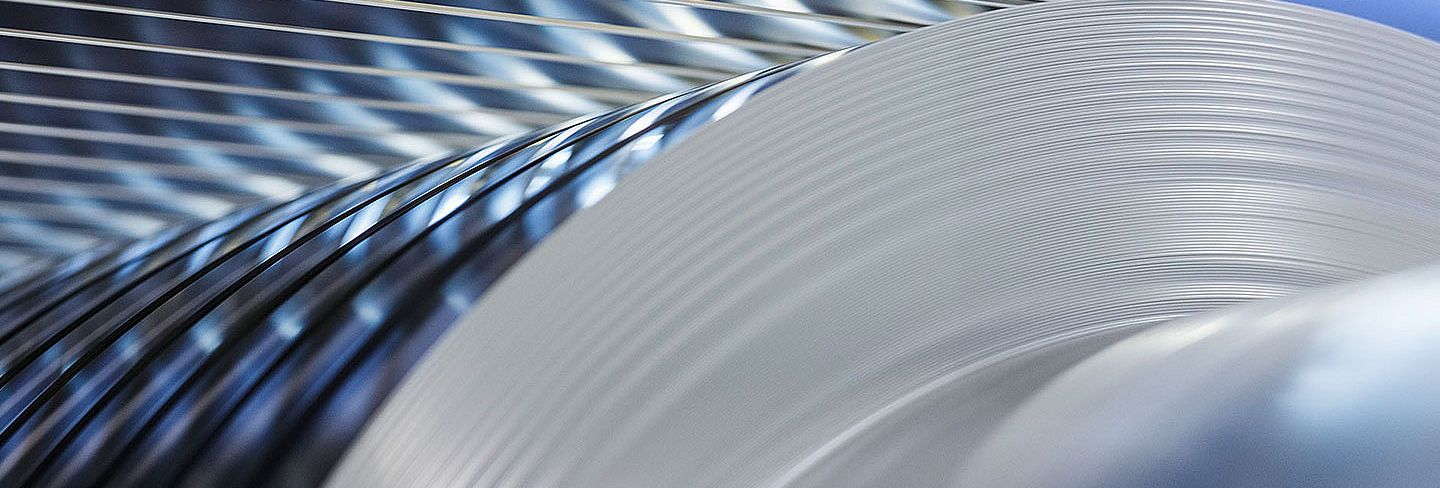

Heat conducting and resistance alloys are mostly found in the electronics industry as specialty wires or as brake and starting resistors for electric drive system. In addition, they are used wherever electrical energy is converted into heat, as in ceramic cook tops, toasters or coffee machines. Heat conducting and resistance materials by VDM Metals are usually available as strip or wires.

Controlled expansion alloys

- Production, storage and transportation of liquefied gases

- Measurement and control instruments for temperatures below 200°C, e.g. thermostats

- Bushes for screwed and riveted joints between dissimilar metals

- Bimetal components and thermostatic bimetals

- Moulds for the production of carbon fiber-reinforced plastic parts (CFRP), especially for aerospace applications

- Frames for electronic control units in satellites and aerospace applications as cold as –200°C

- Support elements for electromagnetic lenses in laser control devices

- Components for the automotive industry

- Lead frames and transistor caps

- Electronic components

Specialty alloys

Materials information and data sheets

Have we sparked your interest? Here, you will find all the alloys in our production, including their relevant data sheets (subject to availability). You can filter our portfolio very simply by type of material, field of application and product form to obtain a quick and uncomplicated overview.