Electronics and Electrical Engineering

Our daily lives are made easier by a wealth of electronic devices ranging from light bulbs to refrigerators and hair dryers to smartphones. In almost every area of our personal and work life, electronic components play a decisive role.

Special electrical, magnetic and thermophysical properties

The ferronickel alloys group exhibits a wide range of distinctive features in its physical properties. The main areas of technical application are supported by the electrical, magnetic and thermophysical properties of these alloys.

Heat conducting and resistance materials, expansion alloys and soft magnetic materials have played a vital role in electronics and electrical engineering for over 100 years. They have many applications in household appliances like hair dryers, electronic motor controls, instrument transformers or current leakage circuit breakers, in the poles of electric motors, transformers, shieldings or as yokes and armatures in relays.

Alloys typically used in electronics and electrical engineering are:

- VDM® Alloy 29-18 (1.3981/UNS K94610)

- VDM® Alloy 42 (1.3917/UNS N94100)

VDM® MAG 50 (1.3922/1.3927/UNS K94840)

VDM® MAG 75 (2.4501/UNS N14076)

VDM® MAG 7904 (2.4545/UNS N14080)

VDM® Alloy HT 70 (2.4658/UNS N06008)

- VDM Konstantan® (2.0842/UNS C72150)

VDM® Aluchrom Y Hf (1.4767/UNS K92500)

Braking and starting resistors

Electronic motor control

Heating elements

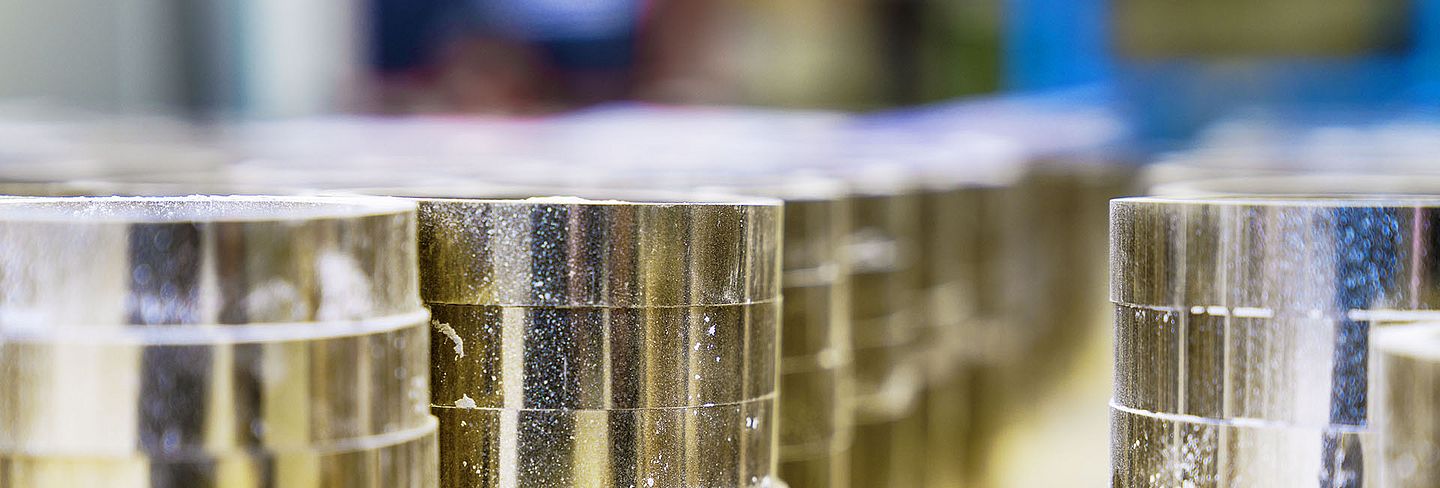

Stamped and bent parts, toroidal cores, current measuring modules and magnetic valves

The soft magnetic ferronickel alloys are divided into two categories. One category consists of alloys with medium nickel content, of which the most important are VDM® MAG 50 and VDM® MAG 53. The second comprises alloys with higher nickel contents, of which the most important are VDM® MAG 7904 and VDM® MAG 75. These alloys are used mainly as stamped and bent parts, toroidal strip-wound cores , current measuring modules and electrovalves.