Contract/toll manufacturing

In addition to our semi-finished products we offer toll work in nearly all areas of our production operations - melting and remelting, hot and cold rolling and a wide range of plant services involving finishing work.

In the field of toll manufacturing, we welcome inquiries about materials outside our own semi-finished product lines, e.g. stainless steels, copper materials or other metal products. Talk it over with us!

Melting and casting (slab, ingot, continuous casting)

- VIM, VAR and ESR

- Induction furnace, EAF/VOD/VLF

Toll Forging

Our modern forging press works with a pressing/compression force of up to 4,500 tons and has two rail-mounted manipulators.

In particular, our forging process has the following possibilities:

- Previous forming simulation based on the finite element method (FEM)

- Real-time recording of the forging process

- Documentation of all data on movements and processes (fingerprinting of very forging) from receipt of the billet to dispatch of the forging to customers

- We are certified to AS9100/EN9100 and ISO 9001 and NADCAP for our furnaces and laboratories

Some basic information:

- 4-column press 45MN (SMS)

- Max. weight 18 t (reversing with 2 manipulators) resp. 60 t (1 manipulator)

- 60 t rotary/lift table , 80 t indoor crane

- Shapes such as billets, rods, (stepped) shafts, discs or special shapes

- Lengths up to 14 m

- Diameter up to 800 mm

- Blank diameter up to 2,000 mm (depending on thickness)

- Wide range of materials such as C-steels, tool steels, RSH, nickel-based alloys, titanium, copper, special alloys, etc.

- A large number of chamber and bogie hearth furnaces (max. length 6 or 7 m)

- Open-die forging

We offer our customers toll forging for the following products:

- Shafts

- Forged discs

- Heavy forged plates

- Steel rolls

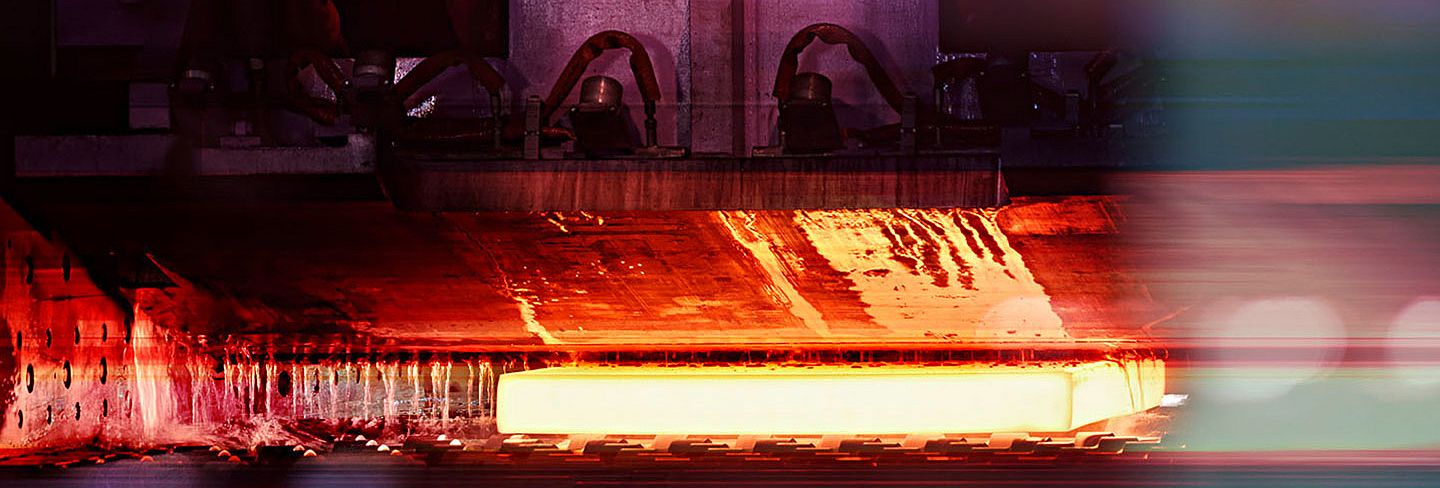

Ingot/slab rolling mill

“B2” Blooming and Slabbing Mill (also referred to as roughing or cogging mill) in Duisburg, Germany.

VDM Metals operates a blooming and slabbing mill, which is capable of converting ingots or slabs of steel (unalloyed or alloyed), stainless and specialty steels, nickel and nickel alloys, titanium and other non-ferrous alloys into slabs or square billets by hot rolling:

- 4MT Duo-Reversible Rolling Mill (Demag)

- Ingot weights between 2 to 27 t, Slab weights up to 25 t with dimensions between 600 to 1.800 mm

- Rolling thickness between 80 to 600 mm or between 100 to 600 mm rectangle

- Maximum Rolling Width 1950 mm (1850 mm net)

- Pit furnaces for heating and heat treatment

- Other sizes/formats upon request/inquiry

This rolling mill is recommendable to produce input sizes/formats for strip, plate or bar production as well for the production of heavy plate.

Our process flexibility and tremendous speed of this conversion process, results in one of the most cost-effective hot forming processes available for the conversion of ingots or slabs into smaller dimensions for further processing.

Four-high hot rolling mill

- Cutting of slabs

- Rolling

- Heat treatment

- Levelling/pickling/cutting

Cold working

- Cold rolling of strip

- Cold rolling of sheets with widths up to 2,600 mm

- Drawing of wires and rounded products (e.g. cold drawn tubes)

Finishing work/adjustment/ultrasound testing in long and flat products

- Mechanical processing (peeling, turning, grinding)

- Heat treatment

- Descaling, sand-blasting and pickling of round and flat products

- Testing services (examples)

- Ultrasound testing in contact and dipping techniques

- Qualification/Certification according to DIN EN ISO 9712, DIN EN 4179 level II, III, NADCAP dipping techniques, testing to AMS/DIN EN/ASTM, etc.

- Ultrasound testing for rod dipping techniques (diameter 90 – 400 mm; length 900 – 6000 mm)

- Ultrasound testing for sheet metal dipping techniques (thickness 5 – 100 mm; width up to 2500 mm, length 500 - 8000 mm)

- Lab testing/material testing on request